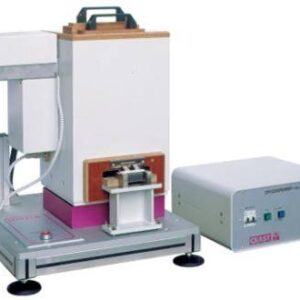

| Electronic: |

| • charlyrobot CNR2 micro-step digital control. • 3 interpolated electronic axes. • Communication: RS232C. • Power supply: 230 V single phase. • Installed power: 2 kW with HF spindle 1,1 kW. |

| Drive: |

| • Stepped motors, micro-step management. • Ball screw diameter 12 mm with a thread of 5 mm on X, Y and Z. • Guides by prismatic rails with ball recirculation shoes on X and Y. • Protection of axes by lip seals on X, Y and Z. • Greaser on guide shoe and drive ball screw bushing. |

| Options: |

| • Micro lubrication. • Floating suction sensor in Z, for 2D application only. • Standard 600 W spindle with speed converter by mechanical potentiometer on the spindle. Rotation of 8 000 to 24 000 rpm. Maximum tightening diameter of 8 mm. • High Frequency spindle 1,1 kW without tool changer with electronic frequency converter controlled by potentiometer on the front panel. Rotation of 6 000 to 24 000 rpm, EX20 collet with maximum tightening diameter of 13 mm. |

| Safety: |

| • Integral cover with 180° vision, very bright. • Compliant with the European Directive “machine n° 98/37/CE”. • “Punch button” type emergency stop. • Cover opening detection. • Electromagnetic cover locking, controlled by the spindle. |

| Features | |

| Stroke in XYZ | 310x220x160 mm |

| Table size | 375×330 mm |

| Architecture | Fixed gantry with mobile table in Y |

| Structure | Tack welded steel |

| Passage between column | 450 mm |

| Passage under gantry | 115 mm |

| Passage under spindle nose (1.1 kW) | 165 mm |

| Maximum speed | 100 mm/s |

| Maximum feed rate | 100 mm/s |

| Standard motorization | Stepper motors of 90 Ncm |

| Resolution | 0.003 mm |

| Repeatability | 0.02 mm |

| Machine dimension with cover (WxDxH) | 620x850x730 mm |

| Weight with cover | Approx. 81 kg |