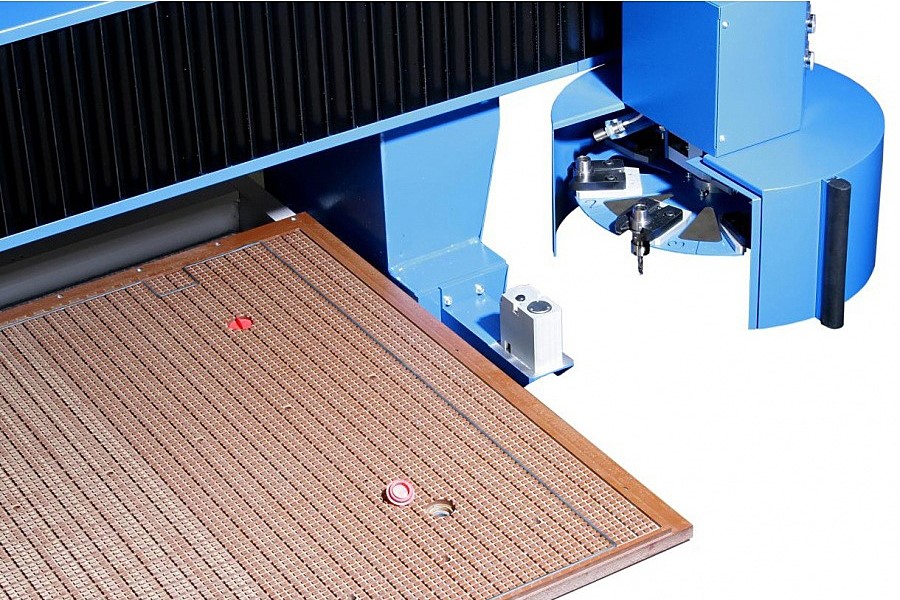

ยี่ห้อ Mecanumeric รุ่น MECA PRO (SIT204)

ได้รับความนิยม ในหมวดกลุ่มสินค้า 3 AXIS CNC Machine

Fix table, moving gantry, the most sold MECANUMERIC range !| ยี่ห้อ Mecanumeric รุ่น MECA PRO (SIT204)

รหัสสินค้า: SIT204

หมวดหมู่: 3 AXIS CNC Machine

ป้ายกำกับ: 3 AXIS CNC MACHINE, For-Plastic, industrial, MECA PRO, Mecanumeric, Plastic-Film, SIT204

Brand: Mecanumeric

*ราคาอาจมีการเปลี่ยนแปลงตามอัตราแลกเปลี่ยน

สอบถามข้อมูล

แจ้งซ่อม/เคลมสินค้า/บริการหลังการขาย

Line

YouTube

TikTok

38 orders in the last 30 days.

1730

Views: 257

|

|

| MECA PRO | |

| For professionals, this 3 axis CNC milling equipment range offers an excellent price ratio/performances, in many industrial sectors. | |

| REFER TO THE EXEMPLES OF APPLICATIONS : | |

| • PVC signboard • Moulds and models • Health case or box • Cases and boxes • Plastics machining • Electric vehicles parts • Parts for subways • Parts for trams • Bus parts • Balloons |

|

| 3 axes Milling equipment : | |

| Precision milling/cutting machine (router) with simple use for machining plate materials in the sectors of advertising, sign, sign board, POP, plastics, aluminium transformation….. Some of the materials to be used (according to the selected spindle and tool) on : – Plastic in rigid plates (PMMA-PC-PS-PVC-ABS..) – Expanded plastic and alveolar plates – Rigid foams (PU- PS-…) – Semi rigid foams (KAPA line®,…) – Composite materials for building : Alucobond®, Dibond®, Reynobond®,.. – Composite materials for industry (polyester resin loaded with glass fiber, carbone fiber…) – Wood and by-products. – Polyester resins. – Light alloys with Aluminium base or copper base. – Steel and stainless steel – Soft stones, marble, granite (only engraving) |

|

| TECHNOLOGIES : | |

| – Structure with fix table and moving gantry. – Welded steel monobloc frame – High inertia welded frame and moving gantry. – Vacuum table in aluminium profiles or composite – Holding of plates by vacuum generated either by side channel blowers, or by claw vacuum pumps. Selection of the zones by manual valves or automatic valves option. – Motorisation : AC Brushless servomotors on 4 axes (X1-X2-Y-Z). Double driving on X axis. – Transmission : high precision ball screw on all axes. – Guidance : grinded steel rails and preloaded ball bearings – POWER AUTOMATION MECANUMERIC CN7000 numerical control with 15 inches touch screen, hardware integrated, Data input by Ethernet link, USB port, import of ISO code files. |

|

| PERFORMANCES : | |

| – Maximum speed : 417 mm/sec- Acceleration : 1 ms²- Repeatability : +/-0.025 mm- Resolution : 0.001 mm | |

| OPTIONS : | |

| – Suction of milling chips by a large range of professional suction device .- Various vacuum tables- Static tool shop or rotative tool shop- Tool coolant by oil spraying – Tool / material cooling system by frozen air .- Multifunction heads options (M3TH) for 3 tools with tangential control Cutting knife for material thickness <2 mm Vibrating cutting knife for light and alveolar materials till 15 mm thickness Grooving tool for packaging application- (GRAFITRONIKS®, OPTISCOUT®, ICUT®) vision registration/compensation system by camera.- Horizontal numerical divisor (4th axis)- SIEMENS numerical control and SIEMENS servomotors- Automatic debatcher for holding material VILMILL®- Multi-head system (2, 3 or 4 heads) for simultaneous machining of several parts- Security zone around machine controlled by radar or immaterial barriers | |

| AVAILABLE SIZES: | |||

Model |

Working travel X mm |

Working travel Y mm |

Z travel standard/option mm |

| MPR1015 | 1020 | 1520 | 250/400 |

| MPR3015 | 3050 | 1520 | 250/400 |

| MPR3020 | 3050 | 2020 | 250/400 |

| MPR4020 | 4050 | 2020 | 250/400 |

| MPR6020 | 6050 | 2020 | 250/400 |

| In option : working length till 7800 mm, working width till 2520 mm | |||

สินค้าที่เกี่ยวข้อง

Stainless Platform Scales

เครื่องชั่งน้ำหนักแบบตั้งพื้นขนาดใหญ่ ยี่ห้อ AXIS รุ่น Stainless Big (BA/N-A) (SIT335)

Stainless Platform Scales

เครื่องชั่งน้ำหนัก ยี่ห้อ AXIS รุ่น Stainless Small (BA/N-A) (SIT337)

Densimeter, Specific Gravity Tester

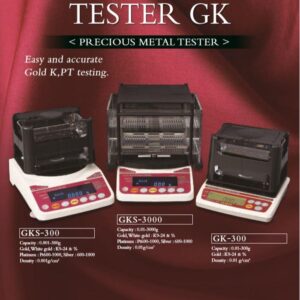

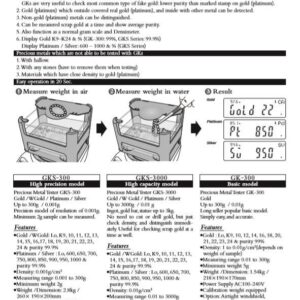

เครื่องทดสอบทองคำ/แพลตตินัม GK (Gold/Platinum Tester GK) ยี่ห้อ AlfaMirage รุ่น GKS/GK (SIT362)