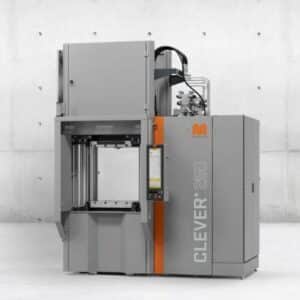

CUTLAM® 5.0

The CUTLAM®5.0 is a pedestal-mounted machine with an integrated recirculation/decanter tank. It represents the ultimate equipment in terms of high-capacity programmable automatic cutting machines. Power and advanced control of the cutting steps will guarantee first class efficiency and productivity.

Wheel and table movements

Technical data CUTLAM® 5.0 |

||

|---|---|---|

| Wheel ∅ | 355 mm (400 mm optional) | |

| Shaft ∅ | 25.4 mm | |

| Standard flanges Ø | 100 mm | |

| Max cutting capacity | Ø 127 mm (with Ø 355 mm wheel) + opening on left and right hand side for long parts | |

| Passage under the wheel | 252.5 mm (Ø 355 mm wheel) | |

| Vertical movement | Z axis stroke 350 mm, speed from 0,1 to 25 mm/sec, speed advanced 50 mm/sec | |

| Longitudinal movement | Y axis stroke 350 mm speed from 0,1 to 25 mm/sec advanced speed 50 mm/sec | |

| Transversal movement | X axis stroke 120 mm (optional) | |

| Lubrication | Recirculation system, 140 litres, on casters Cleaning system integrated, with a shower head outside of the cutting chamber |

|

| Motor power | 5.5 kW | |

| Rotational sppeed | Variable, from 1000 to 4000 rpm | |

| Arm speed advance | 5 to 200 mm/min during cutting | |

| Table | Treated aluminium and interchangeable stainless Steel plate, W 408 x D 422 mm |

|

| Lightening | LED strip | |

| Protection | Cover with locking system | |

| Body | Steel coated with epoxy paint | |

| Pneumatic feeding compressed air | 6 bars filtered 5 µm | |

| Electrical power | 12 kW comcined | |

| Electrical consumption | 32 Ah | |

| Voltage | 400 V – 50 Hz three phase + ground | |

| Dimension (WxHxD) | 877 (+ 600 mm with control panel) x 1727 x 1800 mm (H. cover open 2272 mm) |

|

| Weight | 750 kg | |

| Reference | 60 CT50A 00 | |

Technical characteristics and equipment |

||

|

Theoretical cutting capacity *space under wheel |

||

| A high-capacity, independent cooling/recirculation system (140 liters) is located under the machine. The multipoint nozzles insure excellent cooling of the sample and the cutting wheel even during intensive use.

Fast cleaning is made possible thanks to an exterior shower head and a carefully designed cutting chamber. The wide cutting table: W 408 x D 422 mm is composed of two independent parts. 4 longitudinal grooves and 6 transversal grooves that allow to fix all kind of clamping systems available as options or on the market. |

||

Options |

||

| Machine for cut-off wheel Ø 400 mm | 60 CT503 00 | |

| Laser positioning device | 60 CT506 00 | |

Variantes machines |

||

| Motorised cross-feed table (X axis) stroke 120 mm, accuracy 0.05 mm | 60 CT50A 10 | |

| Motorised cross-feed table (X axis) stroke 380 mm, accuracy 0.05 mm | 60 CT50A 100 | |

Downloads |

||