|

|

| NORMAPROFIL – M SERIES | |

| Fixed table, mobile gantry facing the operator. | |

| REFER TO THE EXEMPLES OF APPLICATIONS : | |

| • Electric vehicles parts • Parts for subways • Parts for trams • Bus parts • Side windows • Aircraft interior furnishing • Parts for the train industry • Parts for racing motorcycles |

|

| Realization of models and moulds or 5 axes machining of vacuum formed, rotomoulded form parts…

MILLING EQUIPMENT OPTIMIZED FOR FOLLOWING MATERIALS: |

|

| • Plastics and composites • PU and PS foams, etc… • Aluminium (as per spindle type) • Synthetic resins • Wood and by-products • Brass and alloys (as per spindle type) |

|

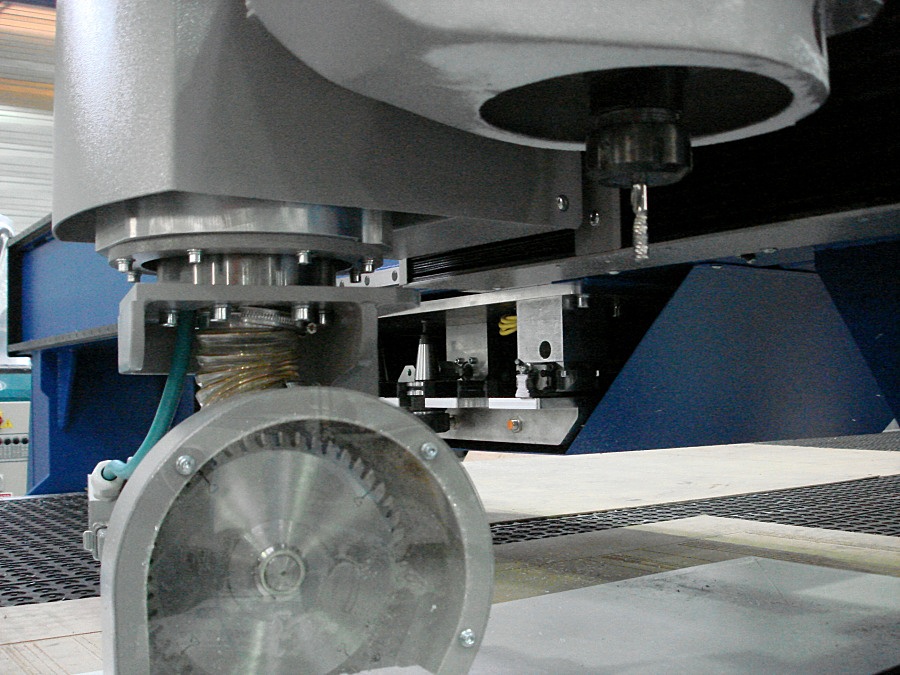

| TECHNOLOGY – 4 AXIS CNC MILLING MACHINE : | |

| • Transmission by ball screws on the 4 Cartesian axes (X1, X2, Y, Z) • 2 rotative axes (C : +/- 200° and A : +/- 200° as per electrospindle) |

|

| Numerical control and motorisation: | |

| • SIEMENS SINUMERIK 840 Di numerical control : X, Y, Z, C, A axes. Colour screen STN 10.4 inches OP010. Brushless motorisation type 1FK7 with numerical variators. Air-conditioned electric cabinet. • SIEMENS SINUMERIK 840D numerical control : X, Y, Z, C, A axes. Colour screen STN 10.4 inches OP010. Brushless motorisation type 1FT6 with numerical variators. Air-conditioned electric cabinet. • NUM 1050 DIGITALE numerical control : X, Y, Z, C, A axes. Flat screen TFT 12 inches. Operator console MP03. Brushless motorisation BPH with numerical variators. Air-conditioned electric cabinet. |

|

| OPTIONS : | |

| • Automatic doors • Vacuum table for parts or tools holding (vacuum technology by turbines with side canal or vacuum pump) • Static Tool shop (6,10,15 tools) • Tool shop driven under gantry (only for M3015) 12 tools • Tool measuring sensor • Sound proofed complete fairing • Double table system for loading / unloading in concealed time (only for M3015) • Other working areas available upon request |

|

| AVAILABLE SIZE: | |||

| Model | Working area X mm |

Working area Y mm |

Travel/working passage Z mm |

| M1510 | 2100 | 1480 | 750 |

| Available electrospindles: | |||||

| Trademark and type | Power (S1)W/HP | Max Rotation | Cooling | Tool clamping | Tool change |

| HSD ES350DS double outlet | 6500/9 | 36000 | Water | ER20 | Manual |

| HSD ES779L-12 | 10000/14 | 24000 | Water | As per tool

configuration |

Automatic

HSK E40 |

| HSD ES789L-16 | 16000/22 | 24000 | Water | Automatic

HSK F63 |

|