|

|

| MECABOND | |

| High productivity 4 axis multi head milling CNC machine optimized for sign applications and frontages in the building area. | |

| REFER TO THE EXEMPLES OF APPLICATIONS : | |

| • Aluminium frames • Plastics and PVC frames • Decorative friezes • Building façades |

|

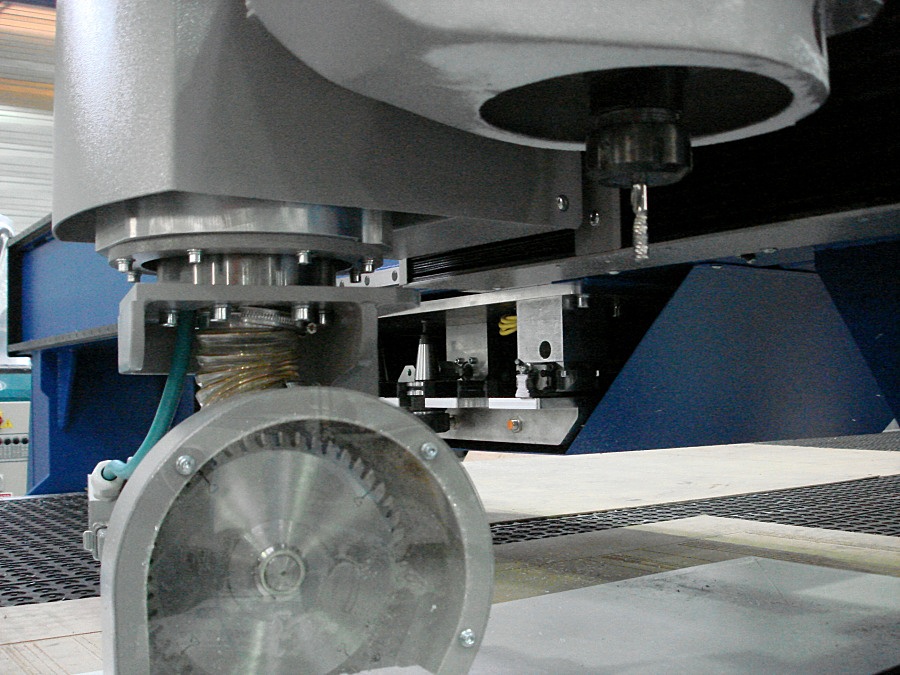

| Milling equipment – 4 axes multi spindles: | |

| High productivity system for fast cutting of materials in plate in the building sector (facades), POP sector or fitting sector of commercial vehicles (refrigerated trucks,…)

This 4 axis CNC milling machine can be equipped with a strong powered vertical electro spindle and horizontal electro spindle, adjustable on 360 degrees. Materials to be used on (according to the selected spindle and tool) : |

|

| TECHNOLOGY – 4 AXIS CNC MILLING MACHINE : | |

| – Structure with fix table and moving gantry. – Welded steel monobloc frame – High inertia welded frame and moving gantry. – Vacuum table in aluminium profiles – Holding of plates by vacuum generated either by side channel blowers, or by claw vacuum pumps – Automatic selection of the zones by electro valve . Plate reference thrust automatically retractable – Motorisation : AC Brushless servomotors on 6 axes (X1-X2-Y-Z1-Z2-C) – Transmission : high precision rack and pinion on XY axes and ballscrew on Z axis, reducer without backlash on C axis. – Guidance : grinded steel rails and preloaded ball bearings – Numerical control MECANUMERIC CN7100 with 15 inches touch screen, hardware integrated, Data input by Ethernet link, USB port, import of ISO code files. – Large range of vertical electro spindle and horizontal electro spindle |

|

| PERFORMANCES: | |

| – Maximum speed : 1000 mm/sec – Acceleration : 1 ms² – Repeatability : +/-0.05 mm – Resolution : 0.001 mm |

|

| OPTIONS : | |

| – Suction of milling chips by professional suction device – different powers – Various vacuum tables – Tool shop integrated under gantry with capacity 6 cones with tool length sensor – Tool coolant by oil spraying – Tool / material cooling system by frozen air – Vacuum areas with automatic selection, controlled by numerical control – SIEMENS SINUMERIK® 840 Di Numerical Control and SIEMENS servomotors – Retractable reference thrust (5 lateral thrusts and 3 frontal thrusts for MB6020) – Automatic debatcher for holding material VILMILL® – Offset electronic handle – Security zone around machine controlled by radar or immaterial barriers. – System of automatic loading unloading by cross bar or interchangeable tables |

|

| AVAILABLE SIZES: | |||

| Model | Working area X mm |

Working area Y mm |

Travel/working passage Z mm |

| MB6020 | 6050 | 2070 | 340/100 |